Lasers in the micrometer range: OpenProject at 3D-Micromac in Chemnitz

Lasers are now the tool of choice when it comes to processing or creating very, very small structures. In areas below 5 micrometers, the selection of suitable tools is very small and the quality requirements are high. Over the past 20 years, 3D-Micromac AG has established itself as one of the leading specialists in laser microprocessing. At its Chemnitz site, the company develops processes, machines, and complete systems that break new ground in the production of semiconductor elements, high-tech glasses, and material analysis. To ensure that the 3D-Micromac brand continues to stand for “high-performance, user-friendly, and future-oriented processes with maximum production efficiency” in the future, nearly 200 employees work at the technology campus, located just behind the venue of the Chemnitz Linux Days.

Solar cells, LEDs, smart eyeglass lenses, and medical technology

The 3D-Micromac laser systems cut cell phone displays and lenses for AR glasses, drill micro-fine holes for medical technology, among other things, and divide PV cells so that they generate electricity even more efficiently. Sven Kunze, Head of Software and Automation (SWAT) at 3D-Micromac, is responsible for automation technology and software, as well as measurement technology. Kunze comes from the world of databases and the web, and was a software developer and team leader in IT before he was allowed to “dive into the real world” at 3D-Micromac AG. He has been responsible for OpenProject at the laser microprocessing expert for four years.

A human-centered SME with dedicated employees

Like many medium-sized manufacturing companies, the Chemnitz-based firm is characterized by a strong sense of community, explains Kunze. Despite all the high-tech involved, working at 3D-Micromac AG is “very human”; employees help each other with the diverse and complex tasks they perform. Another typical feature of medium-sized companies is that the organization of work tasks has long been rather informal and characterized by personal discussions: everyone knew what they had to do — little was written down. This works wonderfully up to a certain team size, but at some point it becomes difficult to keep track of everything.

Before Kunze joined 3D-Micromac AG, the company was already using OpenProject, but project management was handled using a combination of MS Project and Excel. “Because OpenProject was only maintained in a rudimentary way at first, performance went downhill over time and then no one wanted to use it anymore,” says Kunze. “When I made an attempt to get an overview, it turned into a commitment, and it worked.”

Open source: Just give it a try

That’s also the big advantage of open source, says Kunze. Unlike other providers on the market, you can simply try out open source solutions without a lot of formalities such as budget approvals. Things really took off with version 9 back in the days: OpenProject’s WYSIWYG editor (“What You See Is What You Get,” an input tool that immediately displays all formatting changes) was a breakthrough because it always showed what a change in the layout would look like. “This made it usable for people who weren’t tech nerds,” Kunze continues. At the same time, 3D-Micromac was also looking for a wiki system, which was found in OpenProject. Alternatives such as Redmine (on which OpenProject was initially based) were “too complex and nerdy” for the Chemnitz-based company. “We were particularly impressed by OpenProject’s user interface and user experience,” explains the department head.

The fact that OpenProject is open source was important to Kunze, but not a decisive criterion in the pragmatic world of mechanical engineering. Although Kunze heads three development teams, has both an open source and DevOps background, and regularly contributes (“commits”) to OpenProject, he nevertheless emphasizes: “We want stuff that works and can also be used by people who are not tech-savvy. If that happens to be open source, all the better.” Then it can be thoroughly tested before purchase, and Kunze himself can ‘take a look to see if the code is any good.’

OpenProject’s task tracking and user interface were convincing

In the end, the Chemnitz-based company chose OpenProject for task tracking: “This has made task distribution more transparent. Everyone benefits from this, and management can make transparent adjustments” and protect individual employees from overload – with many motivated and self-motivated colleagues, this is sometimes a real issue.

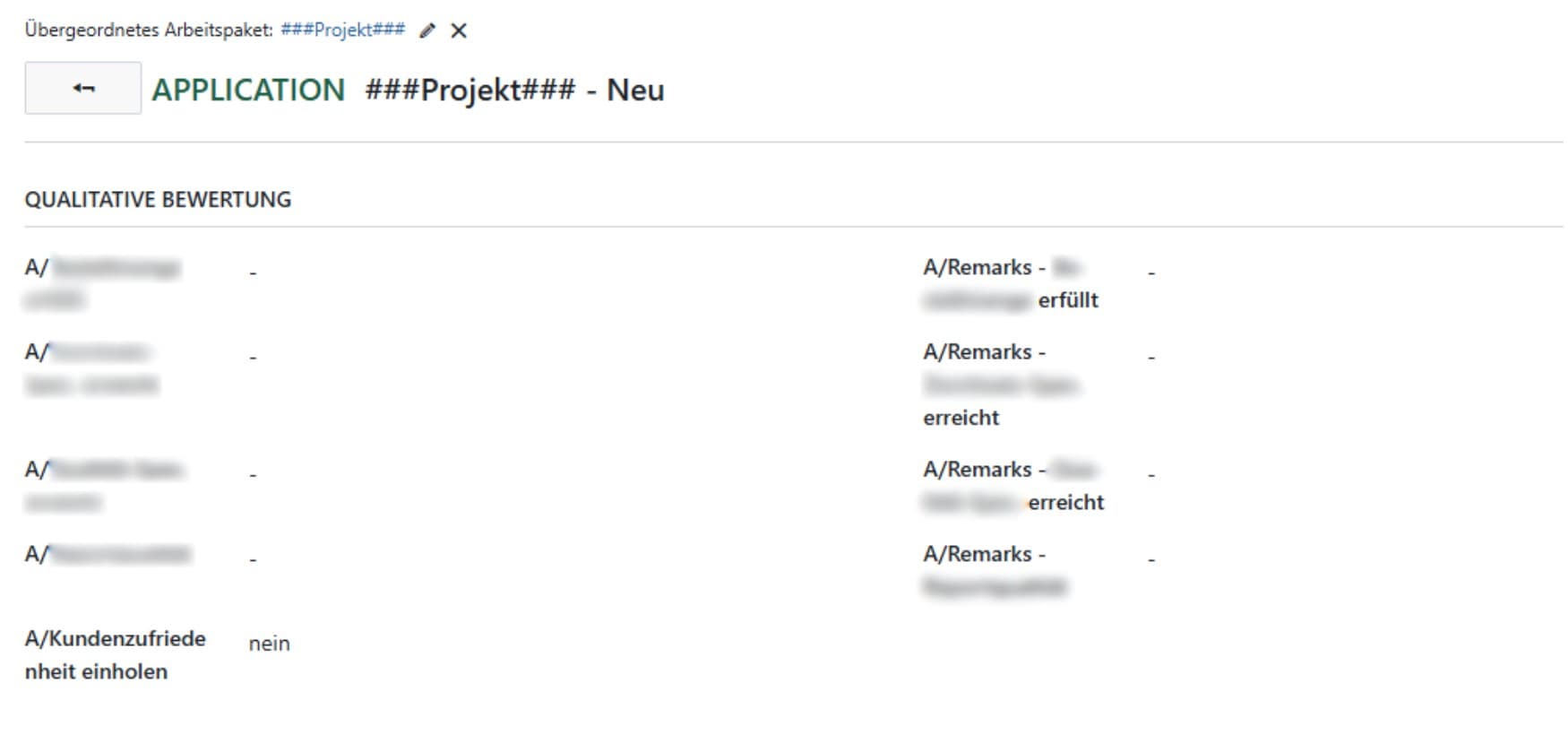

With the help of templates for tasks, tickets, and reports, 3D-Micromac was able to significantly improve the quality of collaboration, which primarily benefits internal customers. “In OpenProject, we mainly use the work package templates, but it also serves as a classic ticket system. The tickets are created from templates in the web frontend – however, we do not use the functionality for inbound emails.” The approach has been “very well received by colleagues, most of whom use it independently and enjoy doing so.”

Flexible, diverse use of OpenProject in departments

The individual departments at 3D-Micromac use OpenProject in very different ways. For example, there is project management with “giant templates” in three to four areas where OpenProject has “grown organically.” For complex machine projects, classic Gantt charts help in most phases, from design to commissioning at the customer’s site. In addition, there is a “phase plan” from above, to which the “trades” are sorted using “sub-phase plans.” “The great thing is that the project manager can see from above whether the bottom-up planning is really working,” enthuses Kunze. “We have set up templates with over 400 tasks. This reflects the complexity of mechanical engineering and occasionally pushes even OpenProject to its limits when setting up new projects.”

Data available from CRM to production

Customer Relationship Management (CRM) is also connected. “In our CRM system, there is a CRM identifier for each request, which we currently maintain manually in OpenProject in a separate field.” For example, orders placed by the sales team in laser contract manufacturing are directly linked to internal task and resource planning.

The sophisticated template system at 3D-Micromac goes so far that employees working on the laser machines can transfer production data, tables, and more directly from OpenProject. “But that’s not all: we also include customer satisfaction, feasibility, quality criteria, and cycle times in project management. This helps immensely because with hundreds of tasks, it becomes impossible to remember all the details. The templates make it much easier to keep your head clear for the actual task at hand.”

On the roadmap at 3D-Micromac: API integration and more

Kunze and 3D-Micromac AG are not running out of ideas. He is currently considering linking the APIs for the ERP, CRM, and HR tools, for example, to automatically integrate absence management. The flexible and open architecture of open source software such as OpenProject makes this easy — even in a medium-sized high-tech company like 3D-Micromac AG.

Header image source: 3D-Micromac AG/Uwe Meinhold