Láseres en el rango micrométrico: OpenProject en 3D-Micromac en Chemnitz

Los láseres son ahora la herramienta preferida cuando se trata de procesar o crear estructuras muy, muy pequeñas. En áreas inferiores a 5 micrómetros, la selección de herramientas adecuadas es muy reducida y los requisitos de calidad son elevados. En los últimos 20 años, 3D-Micromac AG se ha consolidado como uno de los principales especialistas en microprocesamiento láser. En su sede de Chemnitz, la empresa desarrolla procesos, máquinas y sistemas completos que abren nuevos caminos en la producción de elementos semiconductores, vidrios de alta tecnología y análisis de materiales. Para garantizar que la marca 3D-Micromac siga siendo sinónimo de «procesos de alto rendimiento, fáciles de usar y orientados al futuro con la máxima eficiencia productiva» en el futuro, casi 200 empleados trabajan en el campus tecnológico, situado justo detrás del recinto donde se celebran las Jornadas Linux de Chemnitz.

Células solares, LED, lentes inteligentes para gafas y tecnología médica

Los sistemas láser de 3D-Micromac cortan pantallas de teléfonos móviles y lentes para gafas de realidad aumentada, perforan orificios microfinos para tecnología médica, entre otras cosas, y dividen las células fotovoltaicas para que generen electricidad de forma aún más eficiente. Sven Kunze, Director de Software y Automatización (SWAT) en 3D-Micromac, es responsable de la tecnología de automatización y el software, así como de la tecnología de medición. Kunze proviene del mundo de las bases de datos y la web, y fue desarrollador de software y jefe de equipo en TI antes de que se le permitiera «sumergirse en el mundo real» en 3D-Micromac AG. Ha sido responsable de OpenProject en la empresa experta en microprocesamiento láser durante cuatro años.

Una PYME centrada en las personas con empleados comprometidos

Al igual que muchas empresas manufactureras medianas, la firma con sede en Chemnitz se caracteriza por un fuerte sentido de comunidad, explica Kunze. A pesar de toda la alta tecnología que se utiliza, trabajar en 3D-Micromac AG es «muy humano»: los empleados se ayudan entre sí en las diversas y complejas tareas que realizan. Otra función típica de las empresas medianas es que la organización de las tareas laborales ha sido durante mucho tiempo bastante informal y caracterizada por discusiones personales: todos sabían lo que tenían que hacer, se escribía poco. Esto funciona muy bien hasta que el equipo alcanza un cierto tamaño, pero llega un momento en que resulta difícil llevar un control de todo.

Antes de que Kunze se incorporara a 3D-Micromac AG, la empresa ya utilizaba OpenProject, pero la gestión de proyectos se llevaba a cabo mediante una combinación de MS Project y Excel. «Como OpenProject solo se mantenía de forma rudimentaria al principio, el rendimiento fue decayendo con el tiempo y nadie quería utilizarlo», afirma Kunze. «Cuando intenté obtener una visión general, se convirtió en un compromiso y funcionó».

Código abierto: pruébelo

Esa es también la gran ventaja del código abierto, afirma Kunze. A diferencia de otros proveedores del mercado, puede probar las soluciones de código abierto sin necesidad de pasar por largos procesos de aprobación presupuestaria. Las cosas realmente despegaron con la versión 9: el editor WYSIWYG de OpenProject («lo que ve es lo que obtiene», una herramienta de entrada que muestra inmediatamente todos los cambios de formato) fue un gran avance porque siempre mostraba cómo quedaría un cambio en el diseño. «Esto lo hizo utilizable para personas que no eran expertos en tecnología», continúa Kunze. Al mismo tiempo, 3D-Micromac también buscaba un sistema wiki, que encontró en OpenProject. Alternativas como Redmine (en la que se basó inicialmente OpenProject) eran «demasiado complejas y técnicas» para la empresa con sede en Chemnitz. «Nos impresionó especialmente la interfaz de usuario y la experiencia de usuario de OpenProject», explica el jefe del departamento.

El hecho de que OpenProject sea de código abierto era importante para Kunze, pero no era un criterio decisivo en el pragmático mundo de la ingeniería mecánica. Aunque Kunze dirige tres equipos de desarrollo, tiene experiencia tanto en código abierto como en DevOps y contribuye regularmente («commits») a OpenProject, destaca: «Queremos cosas que funcionen y que también puedan utilizar personas que no sean expertas en tecnología». Si además es de código abierto, mucho mejor». De este modo, se puede probar a fondo antes de la compra y el propio Kunze puede «echar un vistazo para ver si el código es bueno».

El seguimiento de tareas y la interfaz de usuario de OpenProject nos convencieron

Finalmente, la empresa con sede en Chemnitz se decidió por OpenProject para el seguimiento de tareas: «Esto ha hecho que la distribución de tareas sea más transparente. Todo el mundo se beneficia de ello, y la dirección puede realizar ajustes transparentes y proteger a los empleados individuales del exceso de trabajo, lo que a veces supone un verdadero problema cuando se cuenta con muchos compañeros motivados y con iniciativa propia.

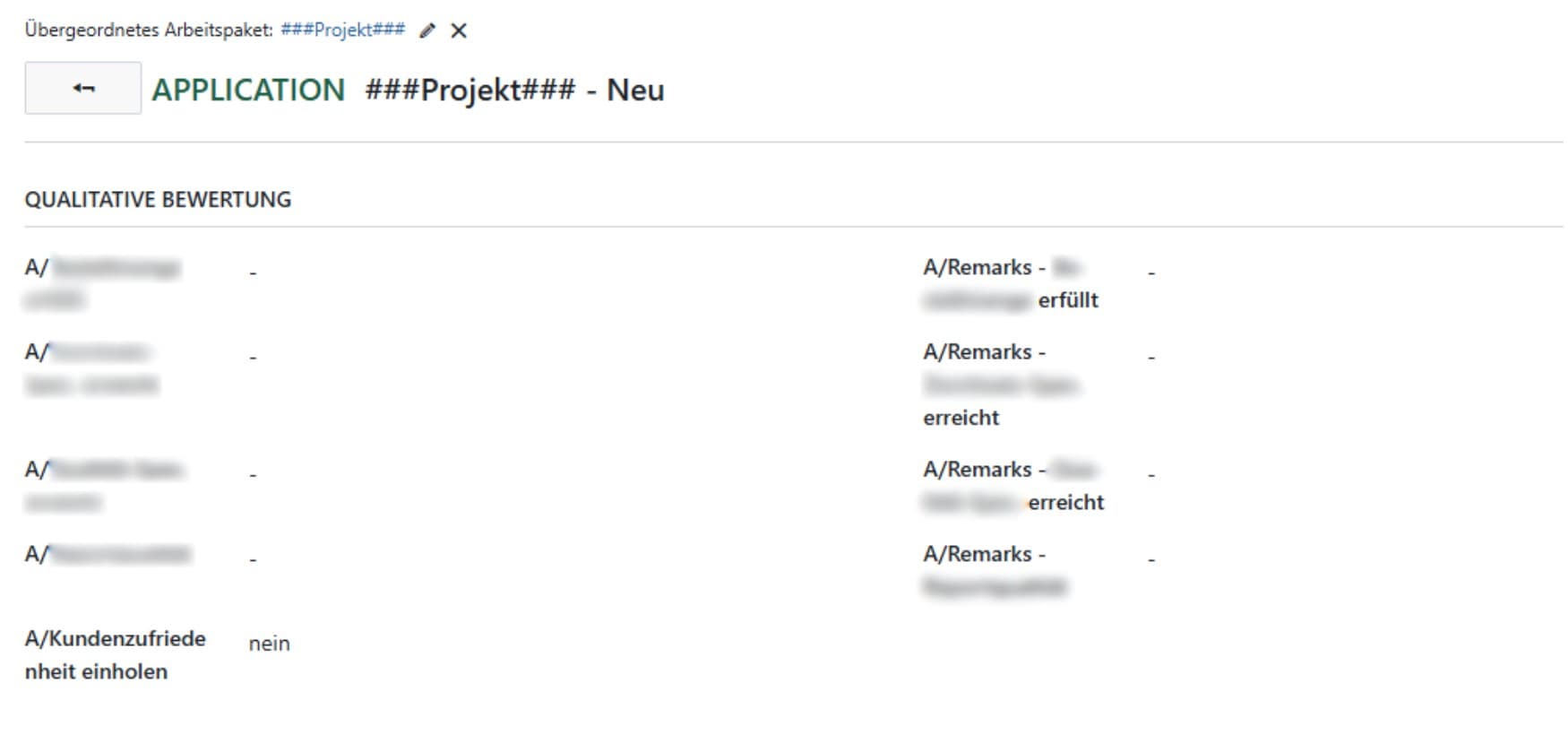

Con la ayuda de plantillas para tareas, incidencias e informes, 3D-Micromac pudo mejorar significativamente la calidad de la colaboración, lo que beneficia principalmente a los clientes internos. «En OpenProject utilizamos principalmente las plantillas de paquetes de trabajo, pero también sirve como un sistema clásico de incidencias. Las incidencias se crean a partir de plantillas en la interfaz web; sin embargo, no utilizamos la funcionalidad para los correos electrónicos entrantes». El enfoque ha tenido «una acogida muy positiva entre los compañeros, la mayoría de los cuales lo utilizan de forma independiente y disfrutan haciéndolo».

Uso flexible y diverso de OpenProject en los departamentos

Los distintos departamentos de 3D-Micromac utilizan OpenProject de formas muy diferentes. Por ejemplo, existe la gestión de proyectos con «plantillas gigantes» en tres o cuatro áreas en las que OpenProject ha «crecido orgánicamente». Para proyectos de maquinaria complejos, los diagramas de Gantt clásicos son útiles en la mayoría de las fases, desde el diseño hasta la puesta en marcha en las instalaciones del cliente. Además, existe un «plan por fases» establecido desde arriba, en el que se clasifican las «operaciones» mediante «planes por subfases». «Lo mejor es que el director del proyecto puede ver desde arriba si la planificación ascendente realmente funciona», afirma Kunze con entusiasmo. «Hemos creado plantillas con más de 400 tareas. Esto refleja la complejidad de la ingeniería mecánica y, en ocasiones, lleva incluso a OpenProject al límite a la hora de configurar nuevos proyectos».

Datos disponibles desde CRM hasta producción

La gestión de las relaciones con los clientes (CRM) también está conectada. «En nuestro sistema CRM, hay un identificador CRM para cada solicitud, que actualmente mantenemos manualmente en OpenProject en un campo separado». Por ejemplo, los pedidos realizados por el equipo de ventas en la fabricación por contrato de láser están directamente vinculados a la planificación interna de tareas y recursos.

El sofisticado sistema de plantillas de 3D-Micromac llega tan lejos que los empleados que trabajan en las máquinas láser pueden transferir datos de producción, tablas y mucho más directamente desde OpenProject. «Pero eso no es todo: también incluimos la satisfacción del cliente, la viabilidad, los criterios de calidad y los tiempos de ciclo en la gestión de proyectos. Esto ayuda enormemente, ya que con cientos de tareas resulta imposible recordar todos los detalles. Las plantillas facilitan mucho mantener la mente despejada para la tarea que se está realizando».

En la hoja de ruta de 3D-Micromac: integración de API y mucho más

Kunze y 3D-Micromac AG no se quedan sin ideas. Actualmente está considerando vincular las API de las herramientas ERP, CRM y RR. HH., por ejemplo, para integrar automáticamente la gestión de ausencias. La arquitectura flexible y abierta del software de código abierto como OpenProject lo hace fácil, incluso en una empresa de alta tecnología de tamaño medio como 3D-Micromac AG.

Fuente de la imagen del encabezado: 3D-Micromac AG/Uwe Meinhold